When constructing and operating recirculating aquaculture system (RAS), farmers depend on the expertise and reliability of their equipment partners. This is the strength global aquaculture solutions provider INNOVAQUA brings to the table.

Based in Seville, Spain, INNOVAQUA has international distribution network, offering comprehensive solutions to the aquaculture and water technology sectors. The company is supported by a team of experts with extensive experience in the design and implementation of projects that incorporate some of the most advanced technologies in the field.

“Our goal is to be a trusted partner for RAS farmers,” said Diego García, partner and manager at INNOVAQUA. “We have the expertise and the technology capable of helping RAS farms address all their technical challenges through a comprehensive service, wherever they are in the world.”

Designed for efficiency

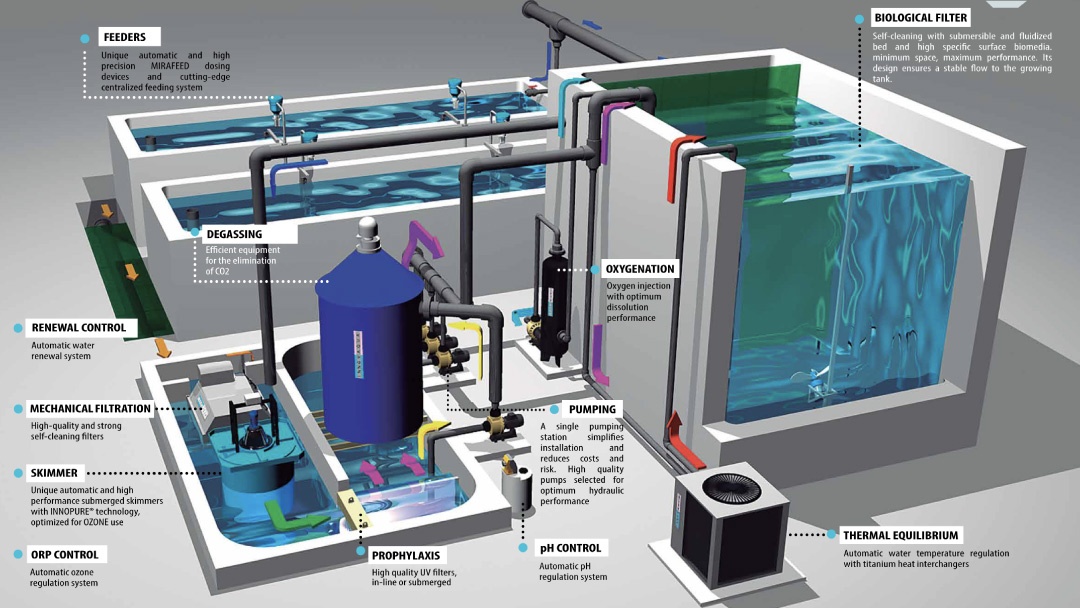

At the core of INNOVAQUA’s technology offerings is the iRASystem, the culmination of the company’s long-standing experience in designing and installing RAS facilities around the world.

iRASystem is an optimised system based on the automated and controlled management of aquatic environments, allowing for efficient water reuse. It is an integral solution to minimise water consumption, optimize production space and reduce energy and operational costs with maximum parameter control.

“iRASystem achieves full effectiveness and efficiency by using the latest technology, materials and equipment of proven quality,” García commented. Some of this equipment is either exclusive to INNOVAQUA or designed, developed and manufactured in-house, such as Innopure, the company’s efficiency submerged protein skimmer.

Optimising water, energy and space

The exclusive and patented Innopure is INNOVAQUA’s high-performance submerged skimmer range that automatically adjusts foam formation, thereby minimising water consumption. With this unique technology, automatic recirculating systems can be designed and installed with outstanding performance, while minimising water and energy consumption, and optimising space utilisation.

Innopure allows the iRASystem to operate from only a single main pumping station, which significantly simplifies installation, reduces energy cost and maintenance.

Easy installation

Depending on the flow rate, connection pipes or control valves can have large diameters that can be challenging to install. Innopure does not require these connection pipes or control valves, which facilitates easy installation.

Reduced energy consumption

Because Innopure is submerged and typically installed in the sump tank, there is no need to lift the water to be treated, therefore significantly reducing energy consumption. It’s an advantage that helps improve a RAS farm’s efficiency and sustainability.

Optimised UV performance

The installation in the sump tank also allows for easy installation upstream of a channel UV, optimising UV performance by reducing water turbidity. This configuration is optimal for circuits with high flow rates by reducing the investment costs of installing a chamber UV.

This also increases the safety of the use of ozone in the skimmer as the channel UV can destroy possible residual ozone.

Water efficiency

The ability to automatically control foam generation adjusts the water consumption to the foam production, which is typically related to feeding cycles. In addition, the flow of micronised bubbles, in countercurrent from top to bottom, centrifuged and again moved from the bottom towards the surface, allows for an interchange of water-air that is definitely superior to any other protein skimmer.

The foam liquefying is made only with suction centrifugation, without adding any water, resulting in large quantities of high-density foam.

High gas transfer rate

The hydro injector is highly efficient and requires low power consumption, producing a very high air injection without pressure losses, resulting in a high gas transfer rate.

Watch the video

Control automation

The iRASystem also includes full automation and control capability through the exclusive Miranda system, which uses state-of-the-art specific sensors, some of them with unique self-cleaning mechanisms. Developed by INNOVAQUA, Miranda enables RAS farms to monitor and manage, in real time, the parameters and key features of machines, sensors and processes in a RAS system, either on-site or remotely.

“For RAS farmers, having visibility across your entire system is key,” said García. “Miranda is an excellent work tool for producers, managers and researchers, with its robust and reliable real-time monitoring and control features of the key parameters and elements of the facilities.”

For more details about iRASystem, visit INNOVAQUA: Specialists in TECHNOLOGY and INTEGRAL SERVICES for AQUACULTURE and WATER TECHNOLOGY