BioMar has reaffirmed its commitment to innovation with the launch of the LARVIVA Hatchery Hub, a state-of-the-art facility designed to replicate the real-world conditions of commercial marine hatcheries. Its mission? To deepen applied knowledge around the use of microdiets during the larval stage.

The quality of fish during these early life stages is crucial to achieving optimal weaning and healthy development through to a high-quality end product at the close of the production cycle.

Raising high-quality marine fish larvae remains one of the aquaculture sector’s greatest challenges. On misPeces, aware of the vital role of innovation centres like this in driving continuous improvement, we visited LARVIVA Hatchery Hub in Hirtshals, Denmark, to meet the team and see their work first-hand.

Located in a purpose-built marine aquaculture environment, the centre currently focuses on gilthead seabream and European seabass as model species. However, its flexible infrastructure allows for trials with other marine species. Its goal is not only to develop and improve microdiets, but to enhance how they are used in real-world production scenarios.

Nutrition is a key element in hatchery feeds, explains Joana Amaral, BioMar’s Global Product Manager Hatchery. “We need to understand what the species actually require in order to grow and develop through the different stages. But it’s not just about that — it’s also about the physical characteristics of the feed, how it’s used, and how we help our customers, each with their own hatchery conditions, get the best possible results.”

For Joana Amaral, this knowledge of species, products, and their correct usage is critical. “I always say-we could have the best larval feed in the world, but if we don’t know how to use it properly, or it’s used in unsuitable conditions, it’s a recipe for disaster.”

Optimising Nutrition in the Larval Stage

The LARVIVA Hatchery Hub is equipped with recirculating, open-flow, and mixed systems, with the ability to control key variables such as temperature and salinity. According to Amaral, this versatility allows the team to work with reproducible models that still adapt to various commercial settings.

These facilities give us an early hands-on experience with the feeds, she adds. “We have a sufficient number of tanks and robust data, which allows us to work with KPIs that closely reflect those of commercial hatcheries. When we talk about high survival rates, growth performance, and initial stocking densities in the tanks, these are key indicators. This setup is fundamental for going further — for truly understanding the requirements and uncovering important insights.”

Customer collaboration is another pillar of the LARVIVA Hatchery Hub’s work. The centre runs bespoke trials based on real needs and help refine protocols to achieve better outcomes. As Amaral notes, “this is a great opportunity to demonstrate the seriousness of our work-and how we can optimise feed use at this critical early stage in the farming cycle.”

Some clients have already visited, she adds. “It’s a very productive setup. We end up having valuable conversations that benefits their daily operations-and ours too. At the end of the day, what matters is responding to the actual challenges our clients face”.

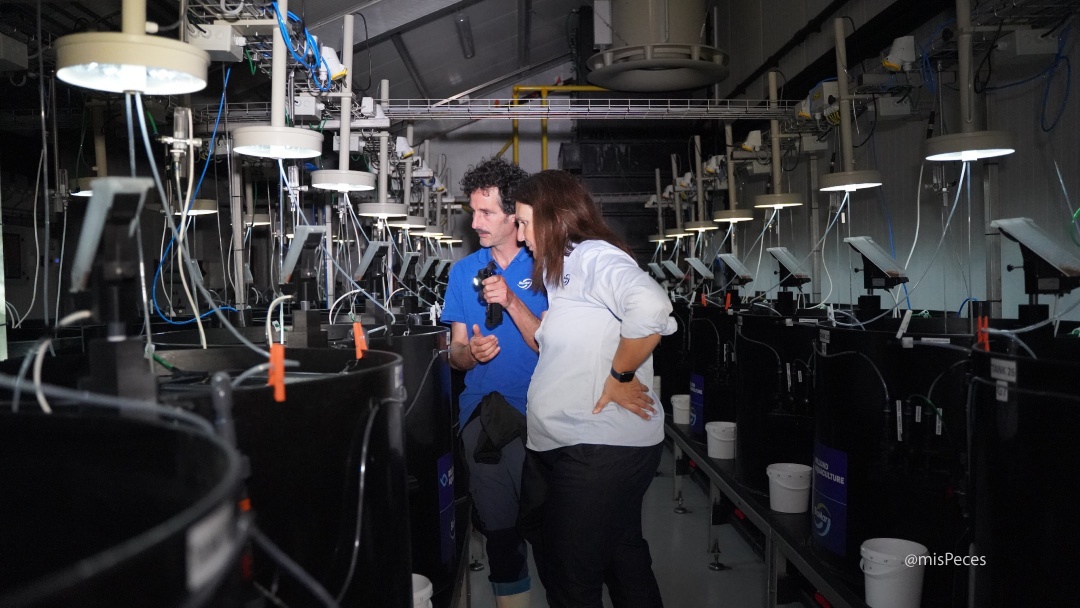

Joana Amaral and Alberto García review the condition of the larvae |@misPeces

Joana Amaral and Alberto García review the condition of the larvae |@misPeces

Operational responsibility at the centre lies with Alberto García, Marine Hatchery Technical Lead, who oversaw both the design of the facility and the implementation of the standard procedures that ensure rigorous, repeatable technical operations. As García points out, LARVIVA Hatchery Hub adheres to industry standards, and thanks to the precision and volume of its work, results are directly transferable to commercial systems.

“We have strong confidence in our data. And the scale we operate at means it can be readily applied across the sector-we’ve already seen this in action,” he added.

Antonio Villanueva, Hatchery Technical Advisor, emphasizes that this centre is pivotal to understanding how larval feeds should perform in hatchery settings. “It’s a strategic development-a vital piece of infrastructure for advancing marine larval diets.” He also highlights the importance of customisation: every hatchery is different, and even large-scale trials must be adapted. “It’s not just about developing a robust product-it’s about understanding how best to use it and tailor it to each customer’s specific needs.”

Results Transferable to the Industry

From the innovation perspective, José Luis González Vecino, Global Innovation Manager, sees LARVIVA Hatchery Hub as a central element in BioMar’s product development strategy.

Crucially, González underscores the role of skilled personnel. “A hatchery is nothing without a team”. As González notes, it is important have trained professionals who know how to feed larvae-incredibly sensitive animals. “Any tiny variations in optimal conditions, environmental conditions, amount of feed that they get, amount of live feed that they get, it has a critical consequence”. “And that as well as the team, the connectivity that the team has with the business and the R&D, that's working the three together that help us to understand how we can make the products better in a way,” added.

This kind of facility showcases how companies like BioMar are leading the way in developing high-value products for industrial hatcheries. The LARVIVA Hatchery Hub acts as a bridge between innovation and practical application at commercial scale.

By validating protocols, fine-tuning diets, and working directly with producers in a controlled environment, BioMar ensures that its solutions are not only based on solid knowledge-but are also practical and transferable.

Joana Amaral - BioMar's Global Product Manager Hatchery

Joana Amaral - BioMar's Global Product Manager Hatchery