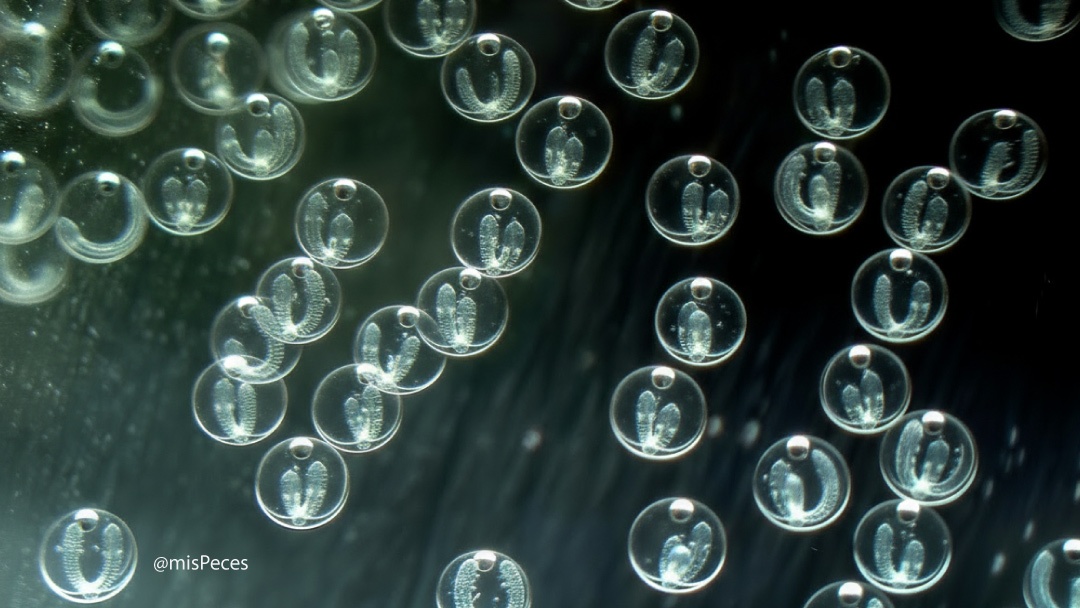

A pioneering system that combines artificial intelligence and computer vision could become a powerful tool for aquaculture hatcheries, improving the classification of fertilised eggs of Atlantic bluefin tuna (Thunnus thynnus) and gilthead seabream (Sparus aurata).

The innovation, presented at Aquaculture Europe 2025 – Valencia, aims to tackle one of the sector’s biggest challenges: early-stage mortality in hatcheries. High-quality fertilised eggs are essential for survival, yet their assessment has until now relied on manual, subjective methods.

The automated system, called the EggSorter, was developed by Swiss company Bionomous in collaboration with the Oceanographic Centre of Murcia (IEO-CSIC). Using an optical system, it analyses each egg individually and assigns it to a quality category before directing it either for incubation or disposal. With a capacity of up to 1,300 eggs per hour, it ensures that only the most viable eggs progress through the hatchery.

Trials with gilthead seabream and Atlantic bluefin tuna eggs, sourced from both captive broodstock and commercial fattening floating cages in Cartagena, Spain, showed that the process did not harm egg viability or larval development. In fact, bluefin tuna eggs sorted automatically achieved a higher hatching rate of 88.5% compared with 83.8% controls.

Founded in 2019 as an EPFL spin-off, Bionomous SA develops AI-driven automation tools for analysing and classifying small biological entities such as fish eggs. Its EggSorter is already being applied in aquaculture to automatically detect, sort and separate viable from non-viable eggs, boosting hatchery efficiency. The company is also advancing AquaSorter, an industry-focused project aimed at species with egg sizes of 1–2 mm, covering up to 40% of farmed species, including many key Mediterranean fish.

Although further optimisation is needed in processing speed and algorithm training, researchers believe the EggSorter could become a vital tool for hatcheries and broodstock management, helping to cut mortality, optimise resources and improve stock quality.