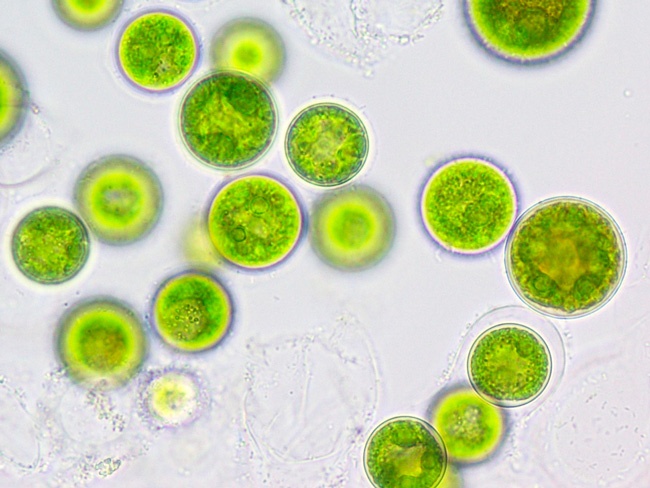

Scientists at the Tiajin Institute of Industrial Biotechnology, part of the Chinese Academy of Sciences, have successfully engineered the microalga Schizochytrium sp into an efficient biological factory for producing astaxanthin-a powerful antioxidant carotenoid with high demand across the food, cosmetics, health and aquaculture industries.

Through a multi-pronged biotechnological approach-combining electroporation-induced mutagenesis, genetic engineering, subcellular enzyme targeting, and fermentation optimization-the team achieved a record yield of 29.5 mg/L of astaxanthin in bioreactor conditions. This represents a 169-fold increase compared to the wild-type strain.

This research, published in the Chemical Engineering Journal, focused on developing a mutant strain named Schizochytrium sp AST32, created by applying high-voltage electric pulses to trigger random genetic mutations. This strain showed an increase in astaxanthin content form 7.56 μg/g to 55.17 μg/g.

Building on this, the scientists overexpressed five key carotenoid biosynthesis genes (idi, crtE, crtIBY, crtZ, and crtW), raising the content further to 374.85 μg/g. By directing these enzymes specifically to lipid bodies within the cells using a fusion protein (PLIN), they ultimately achieved an intracellular concentration of 400.38 μg/g.

Fermentation was then scaled up in a 5-litre bioreactor, employing a glucose-limitation strategy to maximise output. This resulted in a peak production of 29.5 mg/L of astaxanthin, along with 3.83 g/L of DHA, which accounted for 45% of total lipid content.

“This study lays the groundwork for commercial-scale production of astaxanthin through microbial biosysnthesis using Schizochytrium sp, offering a promising alternative to traditional sources,” the authors conclude.