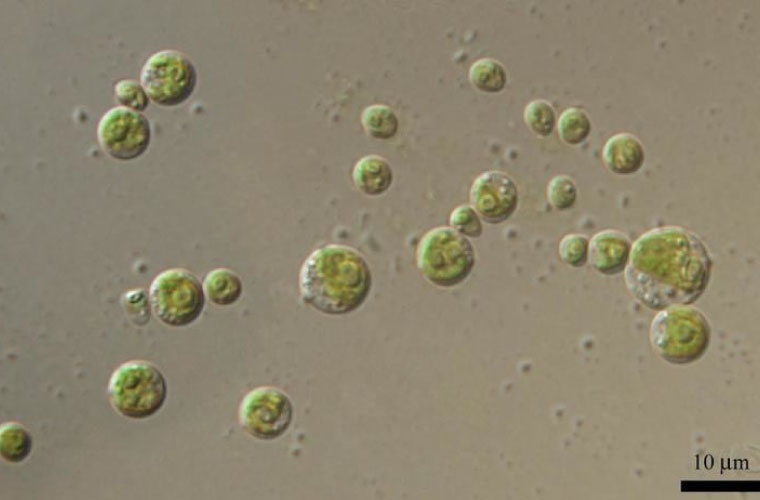

Chlorella sp

Chlorella sp

A Chlorella sp cultivation system that combines Internet of Things (IoT), Artificial Intelligence (AI), and image processing technologies has increased biomass productivity by 7.19% under continuous 24-hour lighting conditions, outperforming traditional 12-hour cycle techniques.

The prototype was developed by Thananop Tummawai and his team at Khon Kaen University in Thailand. Among its innovative features, the system employs non-invasive imaging techniques to monitor growth without requiring physical sampling, thereby reducing contamination risks and improving process efficiency.

An ESP32 camera module, installed within a tubular photobioreactor, captures images of the algae at 30-minutes intervals. The camera is housed in a sealed environment to minimize external light interference and reflections, ensuring clear and high-quality images with a resolution 32x32 pixels. These images are transmitted to a connected computational system, which analyses them to estimate biomass density based on the intensity of green colour. Lower intensity values indicate a higher biomass concentration.

According to the study’s authors, this system places Chlorella sp cultivation at a pre-commercial level that could be easily scaled up. By leveraging smart technologies, it offers a sustainable solution for industries requiring high biomass concentrations, sucha as bioengineering, food production, and pharmaceuticals.

Despite its clear advantages, the adoption of this advanced technology and its integration could involve substantial upfront investment in hardware, sensors, cameras, and automated of machine learning modules, associated software, and energy consumption.