Developing and testing new feeds remains one of aquaculture’s most critical financial bottlenecks. The industry typically faces a ‘black box’ of weeks or months waiting to verify whether a new formulation affects the Feed Conversion Ratio (FCR). However, new research suggests the answer could be available in a matter of days – provided we know how to look.

A recent study led by Hung Quang Tran, from the Institute of Aquaculture and Protection of Waters at the University of South Bohemia, has validated the use of computer vision and deep learning to quantify palatability with unprecedented precision.

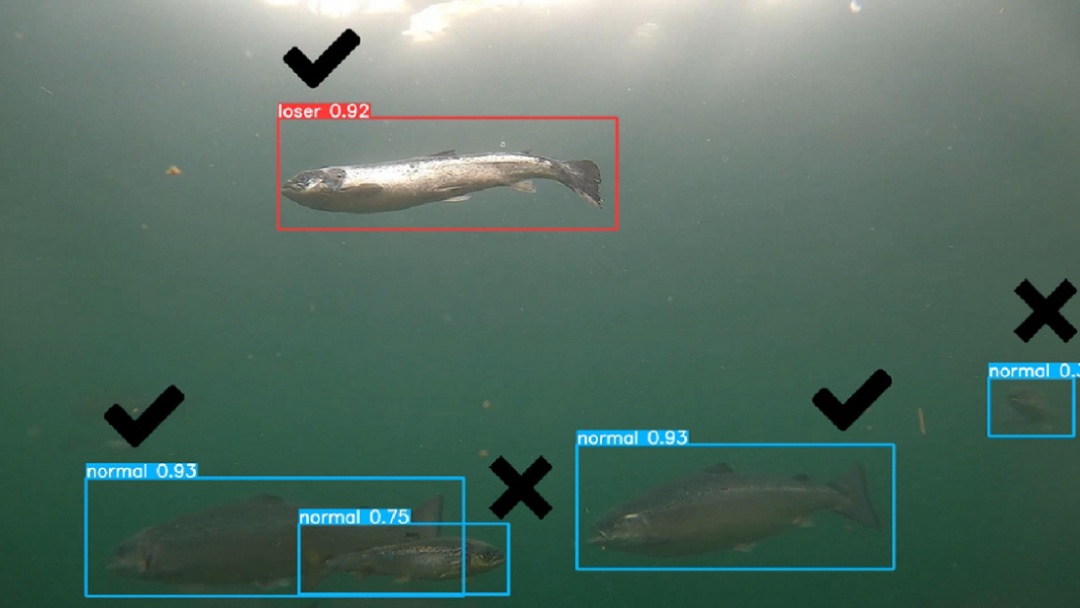

In the study, which fatured collaboration from researchers at the Bern University of Applied Sciences (Switzerland) and the University of Turin (Italy), the YOLOv8 object detection algorithm was utilised to analyse rainbow trout behaviour when offered diets containing black soldier (Hermetia illucens) larvae meal. The results were revealing: the system detected that a 2.5% inclusion of insect meal did not alter swimming dynamics. However, once the 5% threshold was crossed, both ingestion speed and fish activity dropped significantly.

Crucially, the significance lies not merely in the fact that the fish ate less, but that the AI quantified this subtle rejection through behavioural metrics – such as swimming speed and pellet detection – during a short-duration trial.

This tool has demonstrated significant operational efficiency by enabling the early rejection of unsuitable diets. Under traditional methods, subtle shifts in palatability – such as those triggered by volatile compounds (pyrazines) detected in the insect meal during this study – might pass unnoticed until reflected in reduced growth weeks later.

The research concludes that AI does not replace biological trials but rather optimises them by introducing the ‘fail fast’ concept. By detecting palatability issues via computer vision in a matter of days, manufacturers can discard inefficient formulation early. This prevents the typing up of tanks and personnel with low-acceptance diets, allowing for accelerated innovation and the testing of more ingredients without risking the profitability of full production cycles.

The study highlights that these digital tools offer ‘high-resolution and non-invasive’ data, acting as a critical first filter. While long-term nutritional and health validation remains irreplaceable, the ability to predict feed acceptability through automated video analysis promises to drastically reduce the cost of trial and error.

In a market where raw material costs are volatile, competitive advantage will belong not only to those who formulated better, but to those capable of discarding bad ideas faster.